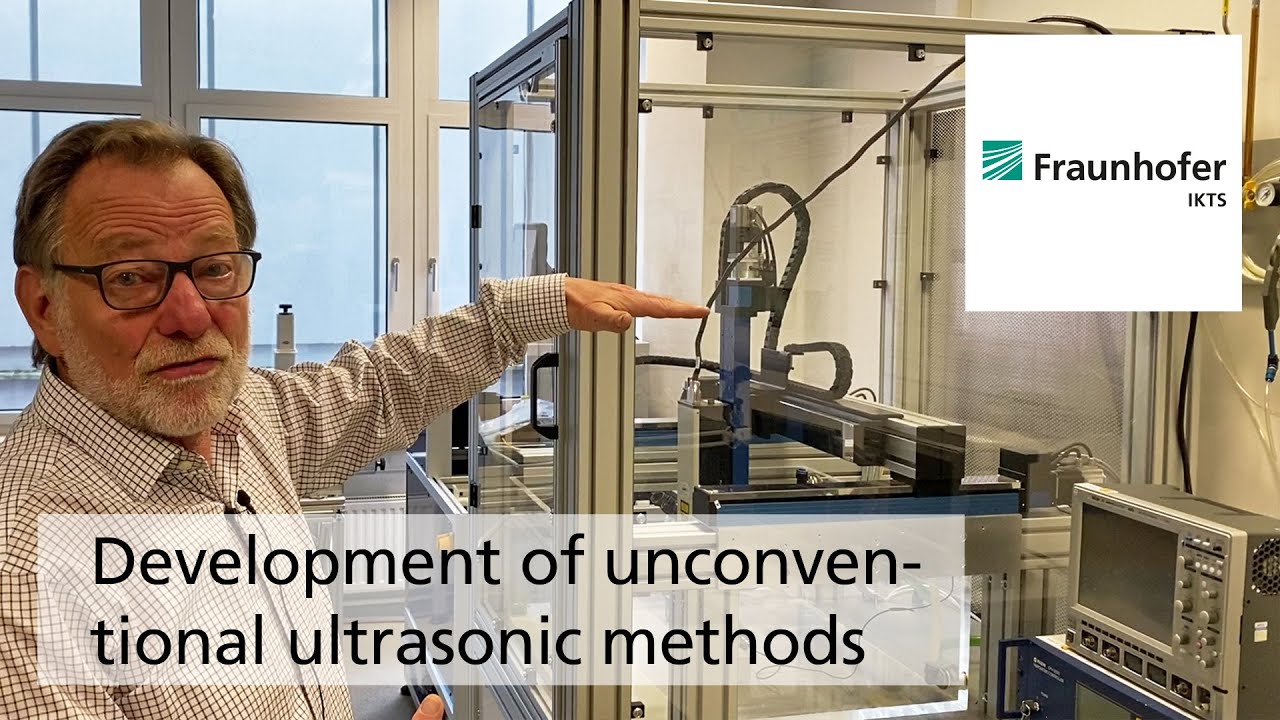

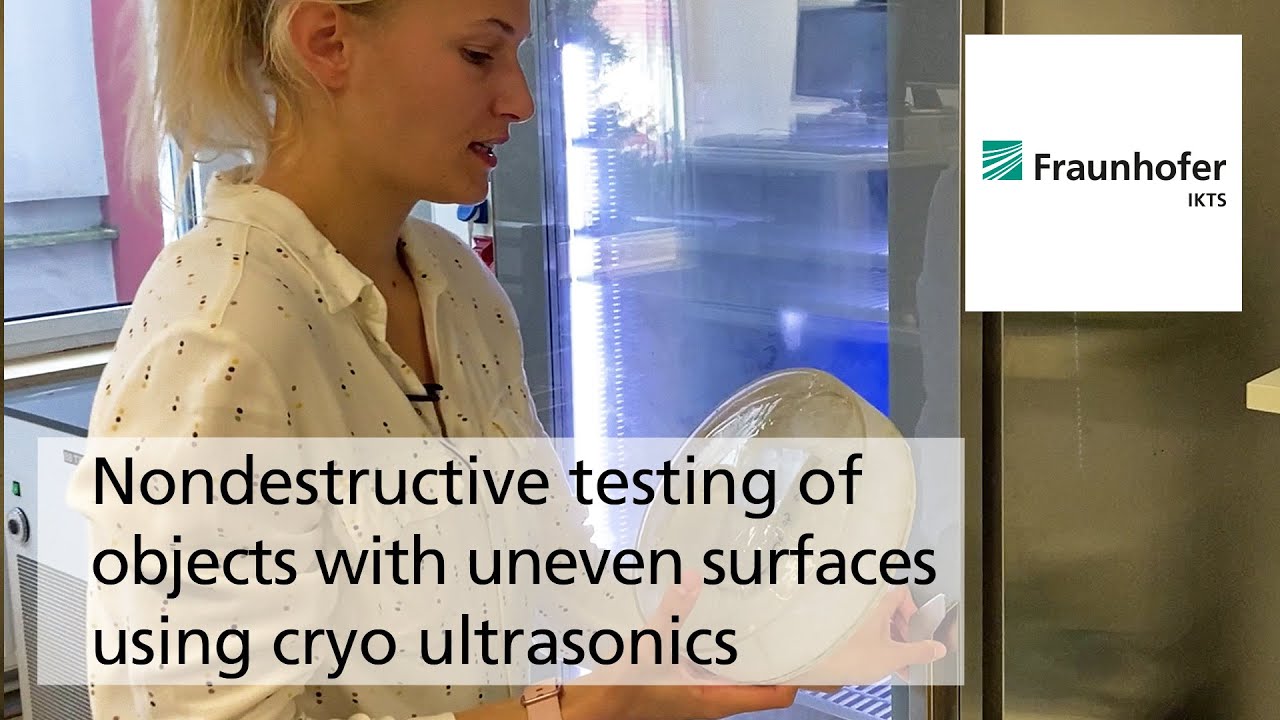

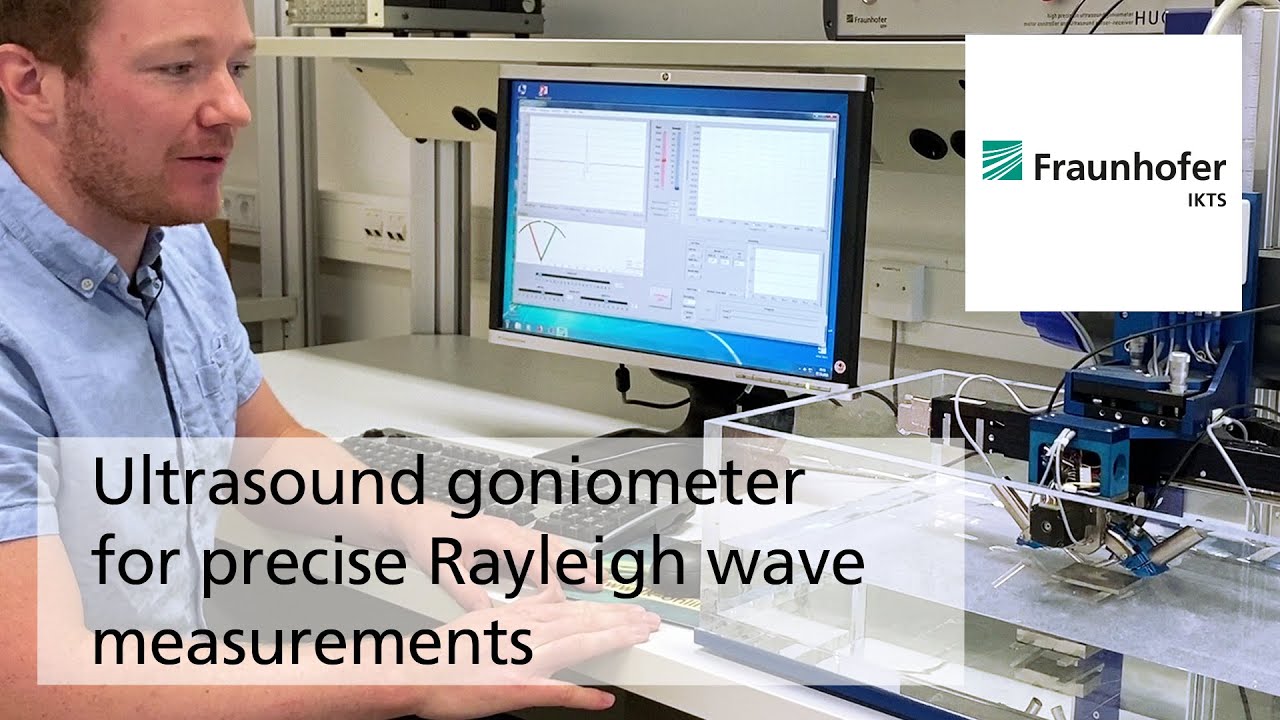

The NDT test lab of Fraunhofer IKTS performs classical non-destructive testing (NDT) for metal, non-metal, ceramic and composite materials. Both standardized and non-standardized NDT methods are used for testing tasks in various industries. These include, for example, mechanical and plant engineering, automotive engineering, rail transport or aviation as well as operators of infrastructures such as power plants and bridges. With more than 20 years of experience, the NDT test lab also offers support for unusual and highly specialized measurement and testing problems.

As an NDT specialist and full-service NDT provider, the test lab has been accredited by the German National Accreditation Body (DAkkS) for individual procedures in the areas of ultrasonic testing, eddy current testing, acoustic emission testing and visual inspection (Accredited NDT Test Lab). In addition, the test lab uses further non-destructive test methods such as X-ray testing, thermography and micromagnetic testing, which can also be used to perform surface and volume testing as well as material characterization on samples of various geometries and materials. The confidentiality of clients as well as the data security of their testing tasks is taken very seriously.