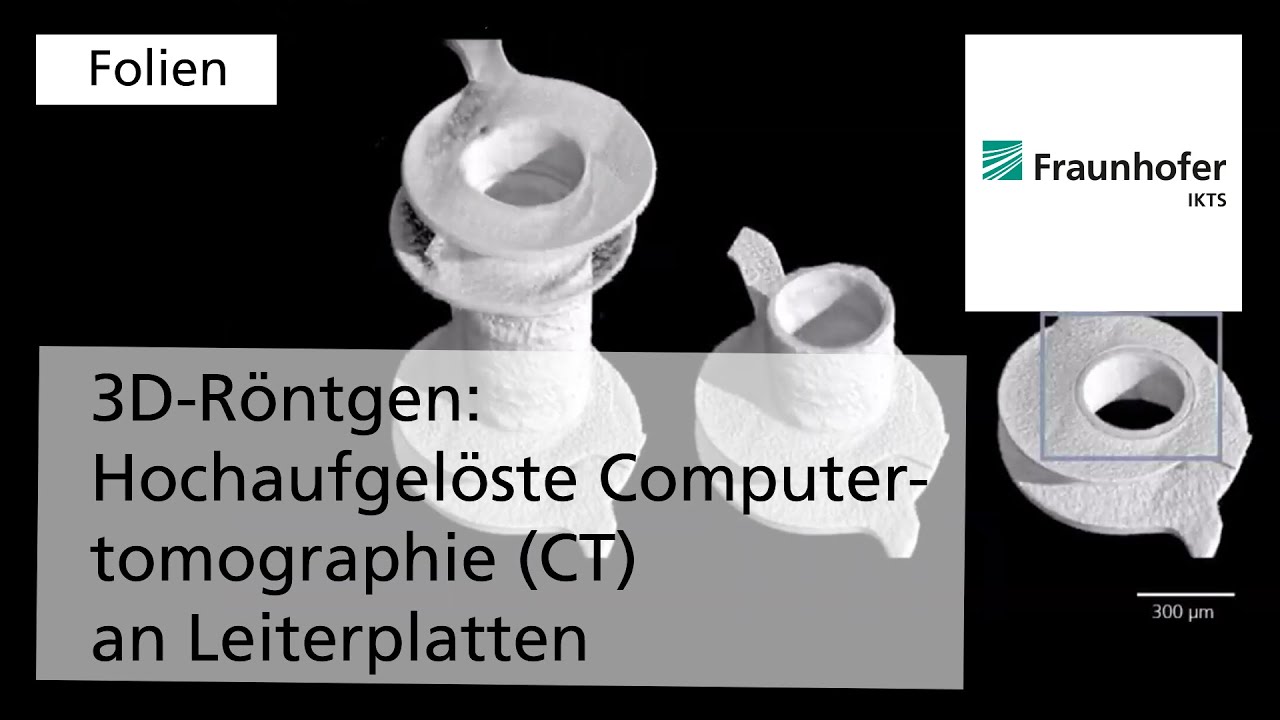

Flat assemblies such as electronic circuit boards can only be examined with insufficient resolution due to their usually large sample geometry. The distance between the X-ray source and the sample is usually too great to examine small sub-areas more closely and to detect the smallest defects such as cracks or pores in solder connections (BGA, QFN, QFP).

Fraunhofer IKTS offers a special X-ray tomography method for this task, which can analyze sub-areas of large-area circuit carriers such as printed circuit boards in high resolution and non-destructively.